Endyn Fabricated Manifolds

As many of you know, several years ago we were one of the first companies to offer radical manifold modifications (with our cut/ported/welded manifolds). Today, stepped-up aerospace contracts have forced AIR to curtail production of their CF manifolds, so we've had to become more "creative" when optimizing manifolding for our head and engine customers.

These fabricated manifolds are optimized for specific engine applications, with plenum shape, volume, throttle body position, runner/plenum intersect, runner length/cross-section, and flange angle as variables.

The plenum shape is configured to eliminate reflected harmonics. Manifold runner entries can be configured for maximum efficiency in forced induction and normally-aspirated applications.

We've placed all vacuum ports on the bottom of the plenum, and we've also configured the manifold to utilize our remote-mount idle control plate to minimize coolant heating.

These manifolds are also available with dual water-necks, and flanges machined to allow the same manifold to be used on B18C1 and B16 heads. Manifolds with CNC flanges and runners are also available for applications where cast manifold flanges and runners are not available.

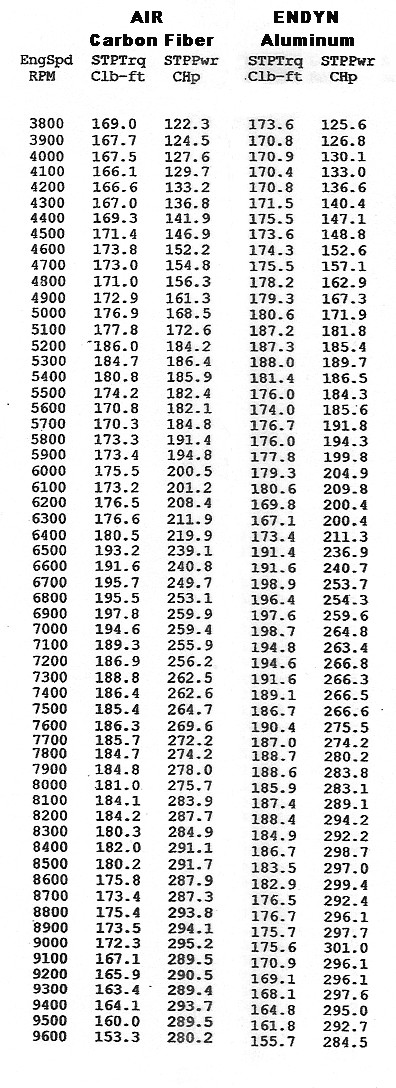

DYNO TEST

In a dyno test session performed on 11-5-05, we compared a carbon fiber manifold to our fabricated aluminum manifold. The test engine was an Endyn-built customer's 2-liter (89mm x 84.5mm) road racing combination. Engine specs include Roller-Wave pistons at 13.0-1CR, Endyn welded CNC head (33.5mm intakes, 27.5 exhausts), Endyn Valvetrain, including Bump-Stix cams, our +.137"Crower lightweight custom rods, sleeved GSR block, mildly modified LS crankshaft, Endyn ITR oil pump, Endyn modified Canton oil pan, Edelbrock 65mm throttle body, and one of our custom large-tube HyTech headers. We've configured this engine to run an entire season with no dependability issues.

These tests were conducted in a 35-minute time span with the engine tuned to 12.8 - 13.0-1 Lamda at all data points. Fuel used was C12. One point of interest is that when equipped with the CF manifold, we were able to reduce total spark timing to 24 degrees for best power. With the fabricated manifold, we were able to make more power with less fuel and less air, with total spark timing reduced to 17 degrees, demonstrating that the combustion event was considerably more efficient. This is the lowest total timing we've run to date on a normally-aspirated B series engine.