Mini Cooper Cylinder Head Modifications

by ENDYN

We've been working with Mini Cooper heads for about a year and a half. Our emphasis has been on increasing flow quality rather than just focusing on bulk-flow quantity. Endyn has .5mm oversize intake and 1.0mm oversize exhaust valves available which when combined with proper portwork, yield impressive power gains throughout the rpm range.

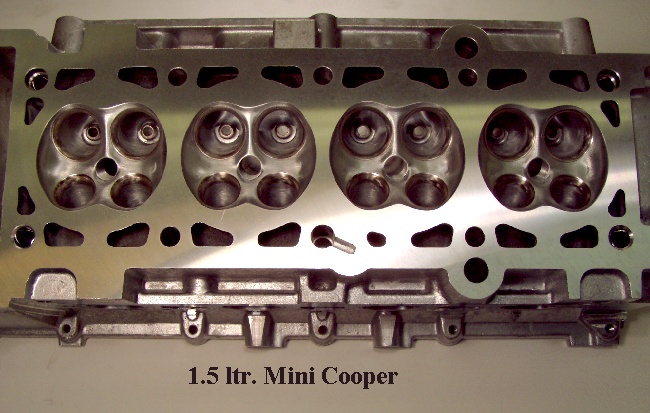

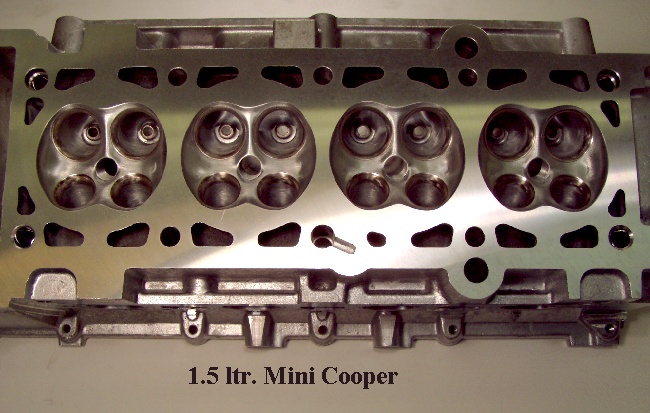

As you can see, our chambers are fully reworked into flow and combustion-pleasing shapes which permit us to raise static compression, while reducing any tendencies toward detonation. As in all our heads, the valve seats consist of a single discrete angle with appropriate compound radiuses leading into the ports and the chambers. This complex seat design greatly reduces turbulence and allows us to flow more air with significantly less port cross-sectional area.

Note that the guides are carefully radiused and blended to eliminate possible sources of mixture wet-out .

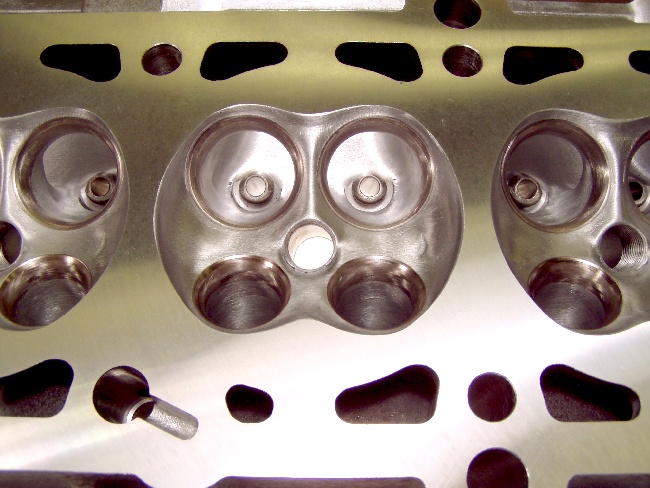

Exhaust ports exhibit a high-level of detail, permitting high flow rates without large cross-sections which would decrease velocity and torque.

MINI Manifolds and Blowers

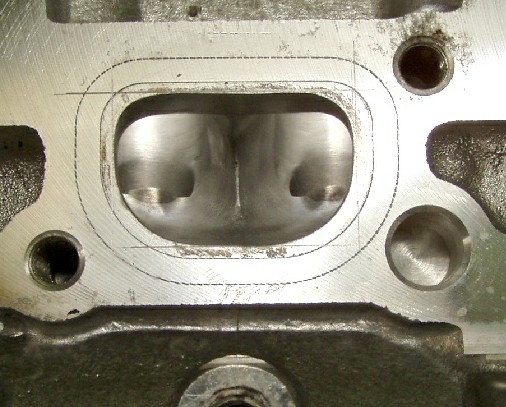

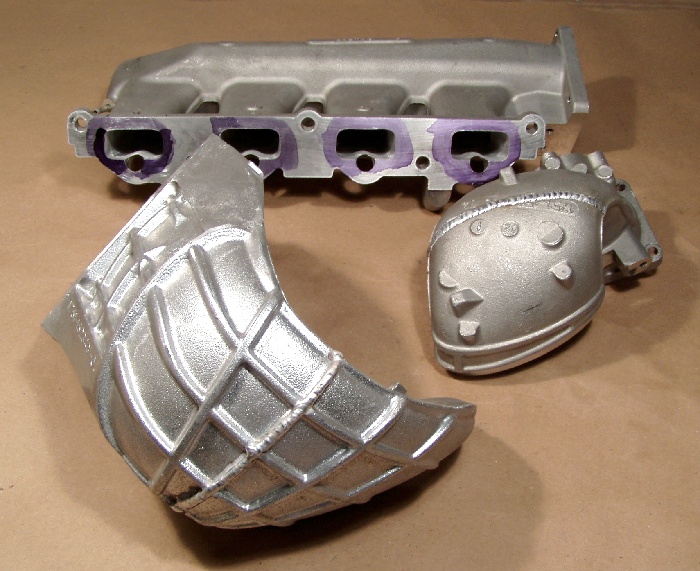

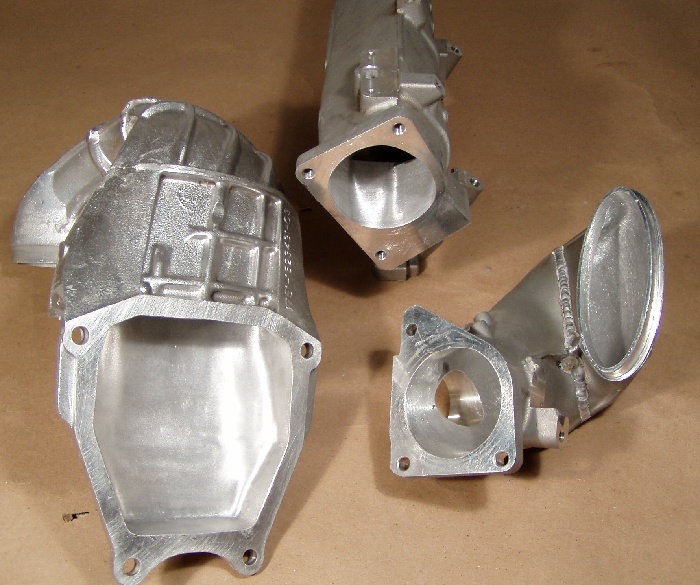

The saying about the chain being only as strong as it's weakest link applies to engine airflow, and to insure that intake manifolds don't restrict flow to our reworked ports, we carefully massage sensitive areas of the manifolding.

While some choose the "easy way" of extrude honing manifolds, we opted to slice the manifolds in pieces, so we could remove material only in the areas that were most conducive to airflow improvements. Extrude honing, while an excellent way of achieving high quality surface finishes, removes material from all surfaces equally, so the final shapes may not necessarily be flow-friendly.

As you can see from the pictures above, the pieces are expertly welded together again after the completion of the shaping.

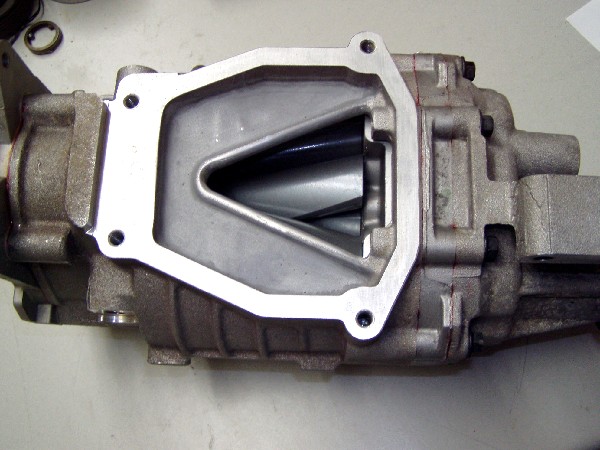

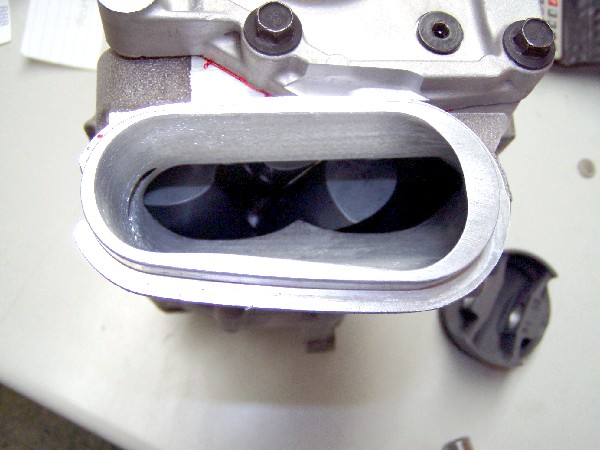

Endyn's been reworking Eaton Superchargers for the public since 1996. The M45 used on the Mini Cooper responds quite well to our efficiency-increasing porting. Below, you'll find a series of pictures showing our modified superchargers. The modifications consist of porting the case to provide precise 120 degree rotor-to-port intervals, as well as welding bridges and then filling the pressure-relief ports, and treating flow entries and exits to flow-friendly radiusing.

To cap off our commitment to Mini performance, we've also designed a forged Roller-Wave piston that works hand-in-hand with the Mini's unique combustion chamber, netting even more detonation resistance, and of course many times the strength of factory pistons. Like all Endyn Roller-Wave pistons, these come hand-radiused brush finished and balanced, so they're ready to install. For those who are really serious, we also have custom billet connecting rods made by Crower to our specifications.